Where knowledge

takes the lead

More than 25 years supporting the manufacturing industry

We provide an unparalleled range of resources enabling you to:

Be effective

Reduce the cost of development

Be advanced

Incorporate the latest material

Be agile

Shorten development time

Be innovative

Exploit advanced manufacturing

Be efficient

With optimised structures

Case Studies

THERMOPLASTIC OVER-MOULDING

Vehicle Torsional Stiffness Improvement

– Combining directional and random composites

– Focussing stiffness where it is most beneficial

– Part geometry development in harmony with structure

– Thickness and layup optimisation

A Hybrid Solution:

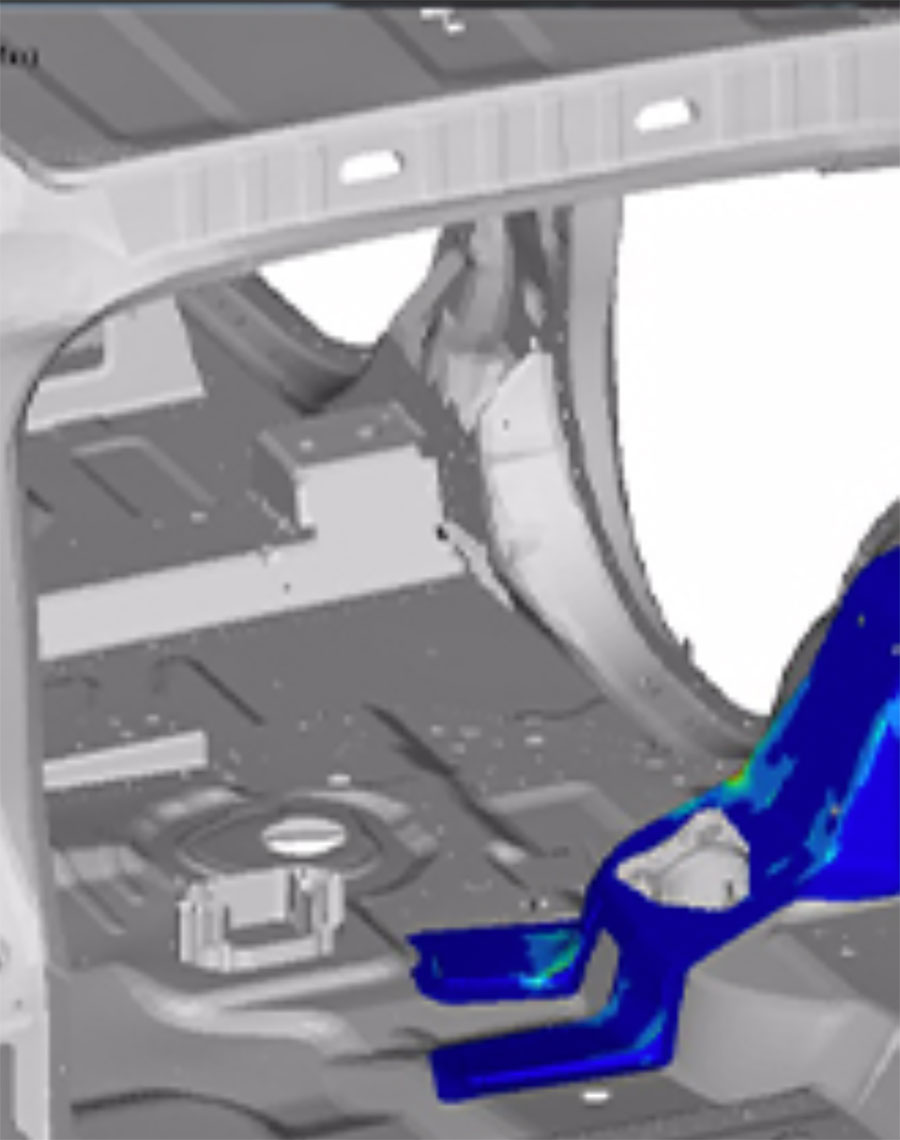

In this project the goal was to maximise the torsional stiffness of an SUV body structure by the replacement of a pair of C-pillar reinforcement panels. The new composite parts would replace aluminium pressings but had to remain at the same weight and crucially be cost competitive.

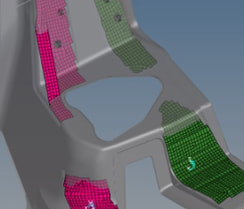

The developed solution was a short fibre carbon filled PA6 injection moulding which incorporated local continuous fibre reinforcements. Predictive analysis was used to optimise the location, extent and layup (fibre direction) of the reinforcements so that the minimum amount of ‘premium’ material was used whilst achieving a significant performance uplift.

The result was an improvement of 7% on the overall torsional stiffness of the vehicle body structure. With the new parts and process, production rates were achievable, cost was comparable, and there was no weight penalty.