Pioneers in materials

and methods

Our Expertise

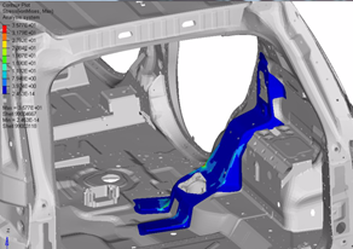

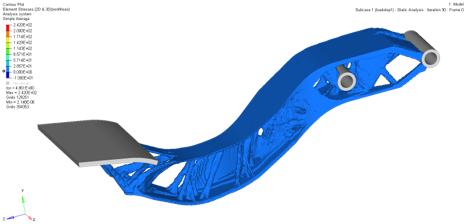

We Optimise Designs to Reduce Weight

Light-weighting is key to performance and material cost. Many components have weight reduction potential, but this can only be identified through analysis. Engenuity have the proven skills and analysis methods to develop lightweight components, whilst ensuring that other criteria such as fatigue strength are met. We offer data acquisition for load recovery and material property testing to provide further opportunities for weight saving.

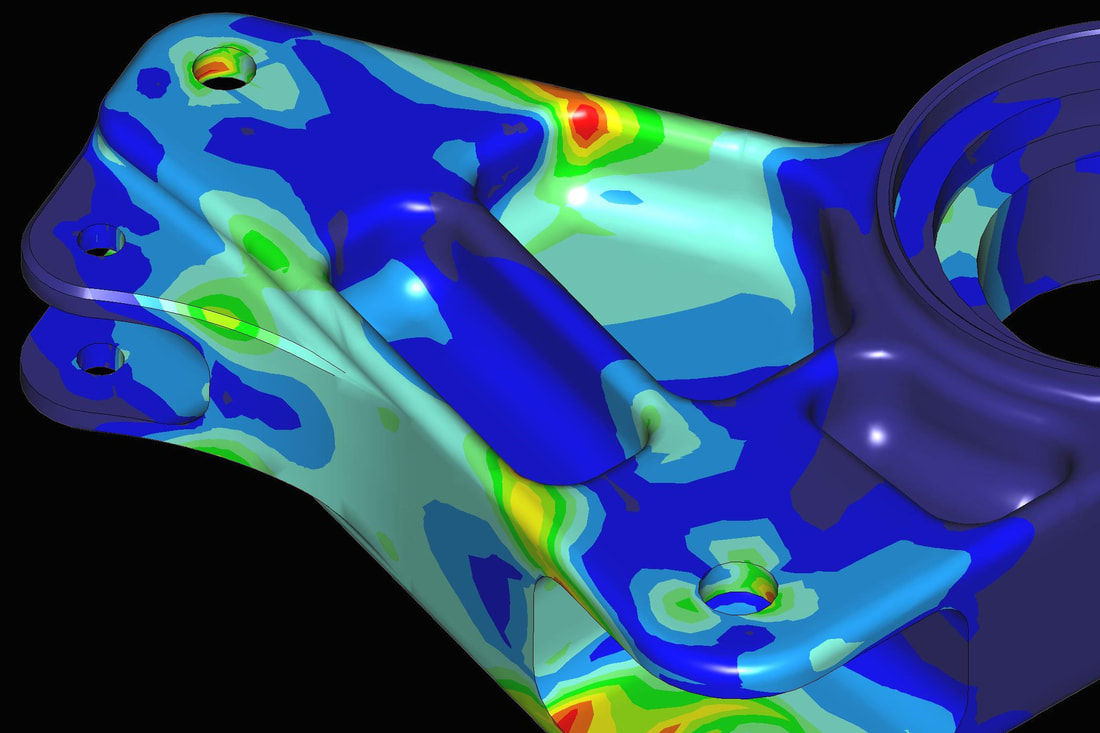

We Increase Stiffness and Strength to Improve Performance

In an ever more competitive market, improving product performance is key. Whether minimising stress levels to ensure long life durability, or increasing stiffness to remove unwanted resonances, Engenuity’s analysis expertise can give you the edge over your competitors. A wide variety of techniques are available to us, so we can provide design support for a huge range of applications, components, and material types.

We Reduce Time to Market

Employing predictive analysis at an early stage in the design process avoids development ‘dead-ends’ and directs the design down the most efficient path. Our cutting-edge techniques, combined with a wealth of experience, result in accurate predictions and reduce the need for prototype phases. Many clients go straight to production tooling on the basis of our analysis findings.

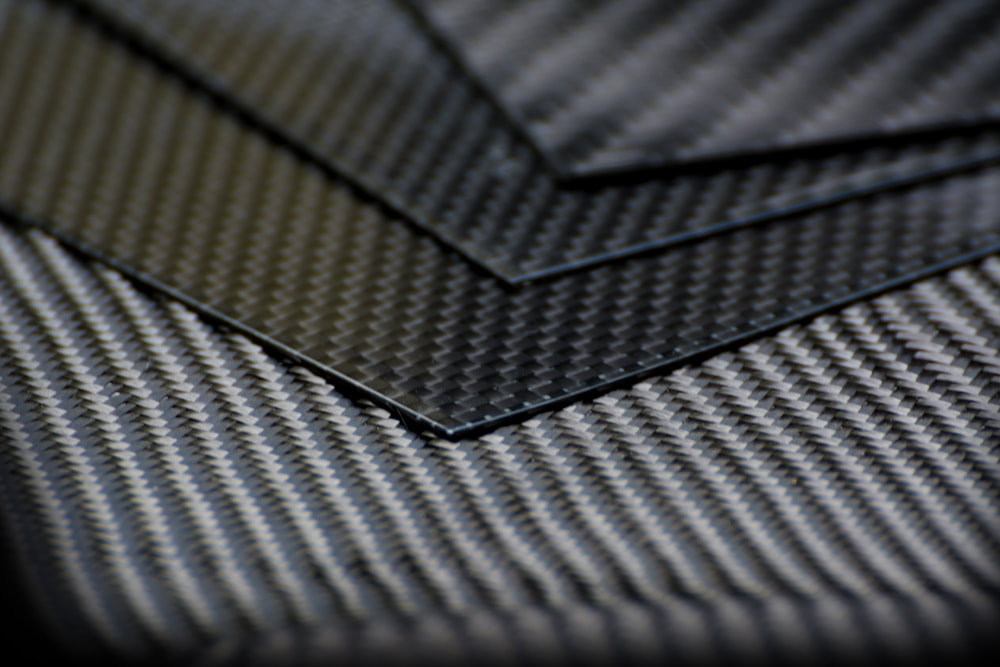

We Identify the Most Cost-Effective Materials

Material choice is of fundamental to the design of structural components. Good knowledge of the mechanical properties in combination with cost, manufacturability and design package space lead to the most efficient designs. Engenuity’s dedicated in-house test laboratory can fully characterise materials, and our experience and understanding of a wide variety of applications means that we can assist you in making the right selections.

Engenuity operates as a composite consultancy to unlock the potential of composites using the latest analysis and testing tools together with a staff of experienced composite engineers.

Through the analysis and development of hundreds of automotive components across motorsport, road cars and truck & bus, Engenuity has a wealth of experience to solve challenges when designing for these vehicles.

We offer detailed analysis simulations of abuse loads and fatigue cycles using real life data acquired through track testing. We can optimize the design of frames, swing arms, yokes, wheels, fuel tanks, and other safety critical components for motorcycles and scooters, IC and electric.

Understand the anisotropy of additive manufactured materials to develop structural 3D printed components. Engenuity’s testing and analysis not only avoids in service failures but also optimizes designs to make the most of the new possibilities in 3D printing. Lightweight parts with less material for faster printing and lower costs, that offer increased strength and durability.

Equipment & Software

As the result of in-house developments to ensure that we can offer cutting-edge analysis and characterisation techniques, we have created dedicated test equipment and software which is now commercially available. CZone and FiRMA analysis extensions (for composite crush prediction, and random material analysis respectively) can be licensed from analysis software vendors Simulia and Altair. Composite crush test fixtures and our bespoke 4.6 kJ Drop Tower can also be built to order.